- Glass container moulds: Ideal for bottles, jars, and other packaging solutions for industries such as food, beverage, and pharmaceuticals.

- Glass tableware moulds: Custom solutions for cups, bowls, and other glassware.

- Cosmetic packaging moulds: Moulds tailored for high-end cosmetic bottles and jars.

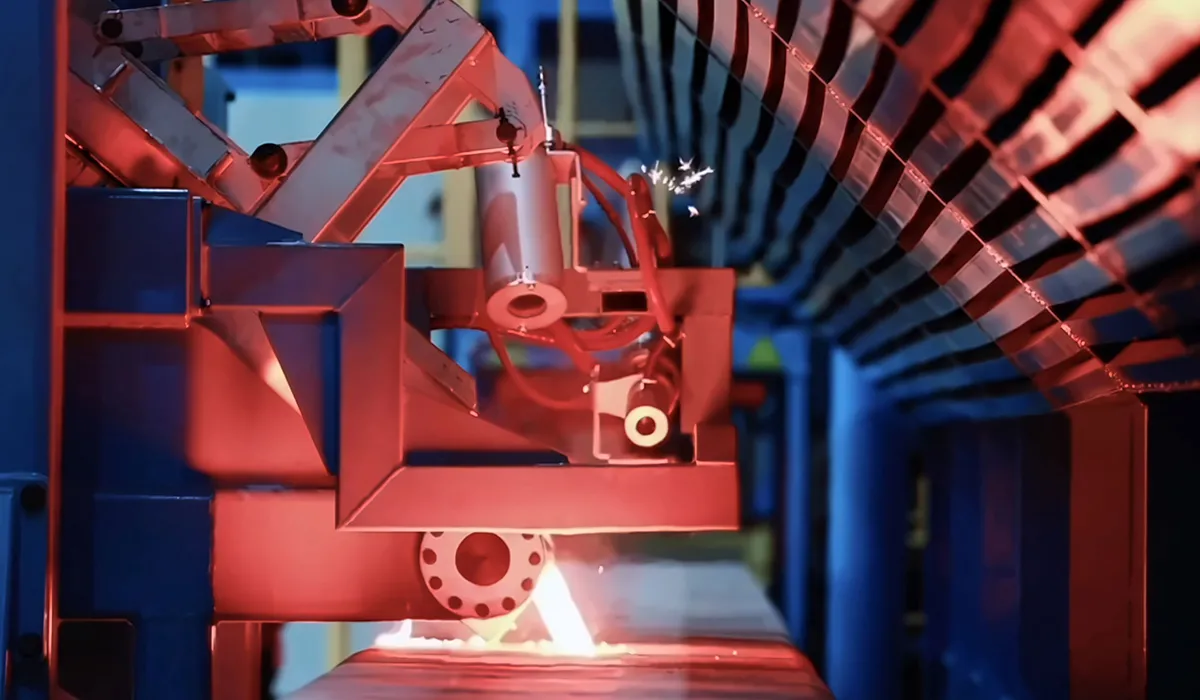

Recognised as one of the global leaders in intelligent glass mould production, we work with over 100 international glass manufacturers. By combining experience with advanced capabilities, we ensure reliable and high-quality moulds that meet the needs of modern glass production.

-

- Glass Container Blow & Blank Moulds

- We utilise advanced flexible automated production lines and intelligent tool magazines, supported by a range of high-precision machine tools that deliver accuracy at every stage.

- Our fully automated casting workshop enables tailored production of high-quality bronze alloys, cast iron, and stainless steel, ensuring materials are carefully matched to client requirements for performance and reliability.

- We operate proprietary turning and milling centres and advanced five-axis machining systems, enabling precise and complex mould production.

- Our full-process MES system ensures intelligent, data-driven management, maintaining accuracy and consistency across all stages of production.

- With 20 years of PTA welding experience, we reinforce critical components such as neck rings and bottom plates to improve structural strength and reliability.

- Backed by over 13 years of laser welding expertise, we achieve precise weld control, ensuring efficient production timelines and consistent quality across all projects.

-

- Glass Tableware Moulds Since the 1990s, ORI Mould has been perfecting the craft of glass tableware mould manufacturing. From elegant cups and durable tumblers to intricately shaped plates, our moulds are crafted to meet strict standards of precision and reliability. Decades of experience combined with advanced techniques allow us to provide solutions that ensure consistent quality and fine details in every product.

- The surface treatment process gives glass tableware a refined texture, enhancing both its appearance and quality.

- Advanced machining techniques deliver precise cavities and complex shapes, ensuring the final product meets diverse aesthetic and functional needs.

- By using stable and reliable casting methods, the moulds offer long-term durability and consistent results, even during continuous production.

-

- Glass Cosmetic Packaging Moulds Our flexible production system is designed to adapt to a variety of bottle shapes and customised designs, ensuring clients' creative concepts are brought to life efficiently. This manufacturing system adapts seamlessly to diverse requirements, whether for complex or highly detailed glass cosmetic packaging. Through our expertise in NNPB (narrow neck press and blow) technology, we provide mould solutions that not only meet high standards of precision but also promote sustainability. By reducing material usage and improving production efficiency, we help clients achieve greener, more eco-friendly packaging solutions.

- Our horizontal machining centres, combined with advanced automated detection systems, ensure high levels of accuracy and consistency throughout the mould production process.

- Automated scheduling systems manage production priorities seamlessly, optimising workflow and enhancing overall productivity.

-

- Glass Mould Accessories

- Precision machining for neck rings and guide plates is achieved using dual-spindle, double-tool cutting technology, which shortens production time while maintaining accuracy. These mould components can be processed in materials such as cast iron, bronze, nickel-based alloys, and Dameron, ensuring durability and performance for glass mould applications.

- Large plungers are produced using the BM901 process, ensuring precision and reliability to meet the requirements of glass mould applications.

- Manufactured using the HVOF (High-Velocity Oxygen Fuel) spraying process, NNPB plungers feature uniformity, wear resistance, and corrosion resistance. This technology significantly extends the product’s service life while improving production efficiency, ensuring reliable performance in glass mould applications.

- We use high-precision CNC machines to produce bottom plates, completing multiple machining steps in a single setup. This method enhances efficiency while ensuring consistent quality and precise results.

-

- IS Machine Spare Parts Besides the various types of high-quality moulds, we supply a range of auxiliary equipment and spare parts to support glass manufacturers in improving efficiency, reducing operational costs, and enhancing competitiveness.

- Machinery and Industrial Robots: Our solutions enhance production automation and quality control processes, minimising manual intervention while improving output accuracy and consistency.

- We offer a complete selection of spare parts for I.S. (Individual Section) machines, the key equipment used in glass bottle manufacturing. These components ensure smooth operation, minimise downtime, and maintain production efficiency.

- Refractory Materials: Designed for glass furnaces, these materials provide long-term stability and optimal performance, supporting efficient and uninterrupted manufacturing processes.

-

- Materials & Castings Our fully automated casting workshop produces high-quality alloy materials and castings to support the glass container and tableware industries. By combining advanced equipment with precise production techniques and affordability, we ensure alloy casting materials and moulds that meet the demands of modern glass manufacturing.

- Cast Iron: With an annual capacity of 8,000 tonnes, we produce casting materials such as vermicular graphite iron and ductile iron, ideal for castings, neck rings, guide plates, baffles, and blow heads.

- Cast Bronze: Our output of 2,000 tonnes includes various bronze alloys used for blow moulds, bottom plates, neck rings, and baffles.

- Stainless Steel: Using a secondary remelting process, this material is well-suited for precision tableware moulds, ensuring reliable performance.

- Nickel-Based Materials: Designed for demanding components like baffles, neck rings, and plungers, providing stability and longevity.