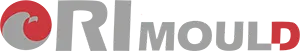

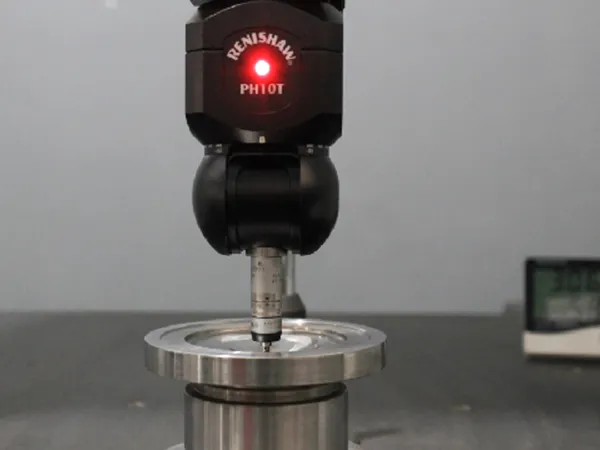

We operate advanced intelligent glass mould production lines with facilities that feature high-end automated machining lines, automated production systems, and horizontal machining centres, combined with an intelligent central tool library. We also utilise proprietary mill-turn machining centres and five-axis simultaneous machining technology, alongside a wide range of precision machining equipment.

The entire production process is managed through the Manufacturing Execution System (MES), enabling efficient process control, data-driven management, real-time tracking, and complete traceability to ensure precision and consistency at every stage of glass mould production.

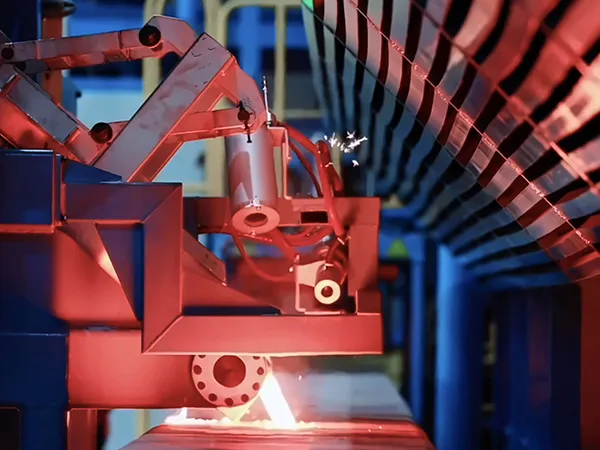

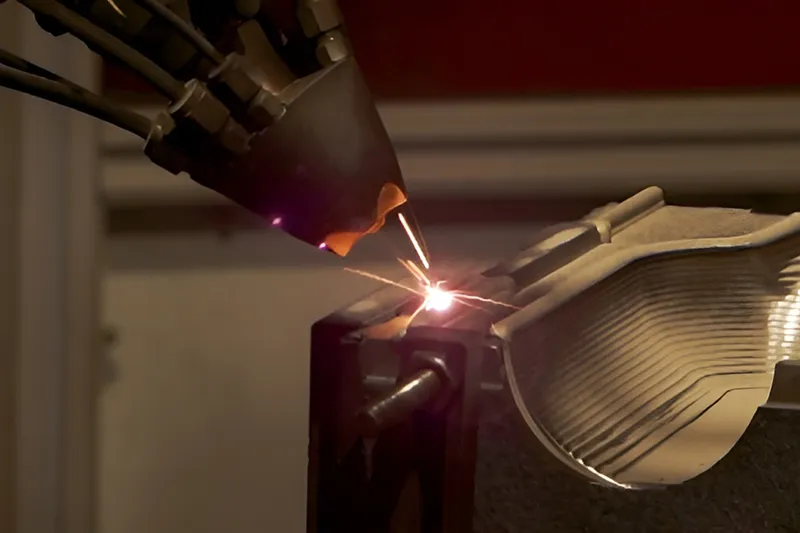

We utilise advanced spray welding solutions, including intelligent laser welding robots from France and fully automated ROBO series welding machines from Italy. This technology minimises damage to the base material, offering precise control over heating area size and coating thickness.

Through eight years of collaborative research with our clients, we have significantly enhanced mould surface hardness and wear resistance, effectively extending the lifespan of our moulds and delivering reliable performance for long-term use.

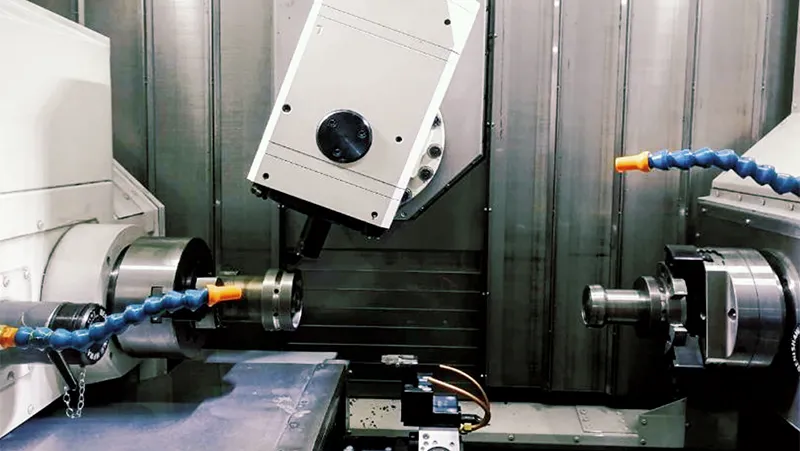

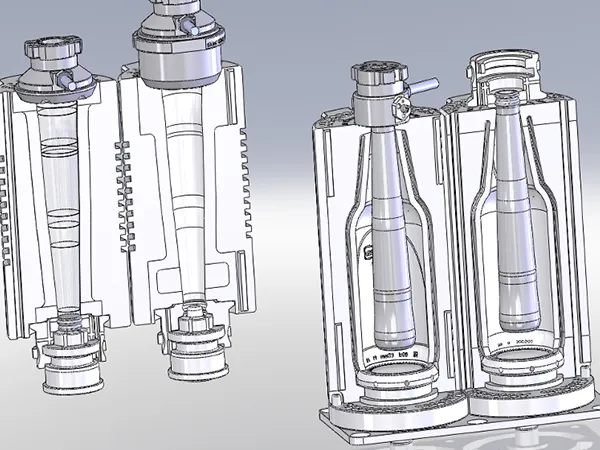

We have adopted an advanced European Flexible Manufacturing System (FMS), enabling efficient production and customised solutions for glass moulds to meet clients' needs for the rapid development of innovative products.

We are also proud to operate the world’s only multi-cavity mould FMS production line, achieving the following:

- Precision with minimal handling: From casting to finished product, moulds require a maximum of three clamping operations, ensuring dimensional accuracy and precise tolerances.

- Enhanced mould uniformity: The system significantly improves the consistency and quality of mould production.

- Shorter lead times: Production cycles are greatly reduced, with mould completion achievable in as little as three weeks.