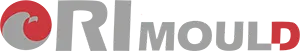

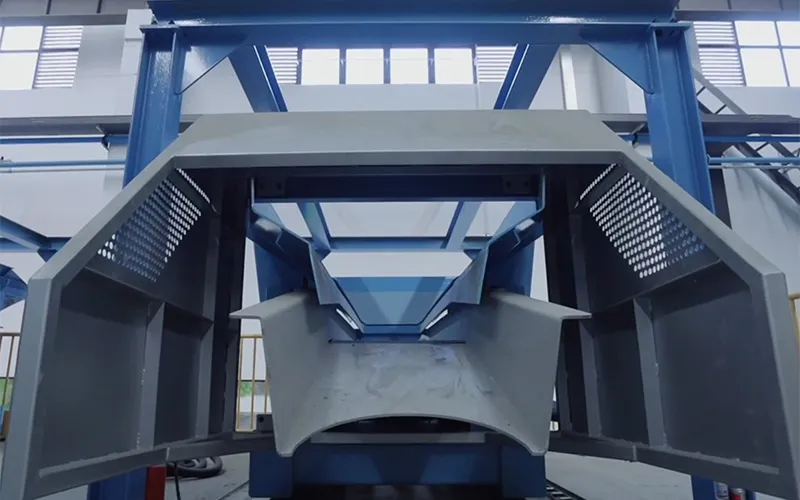

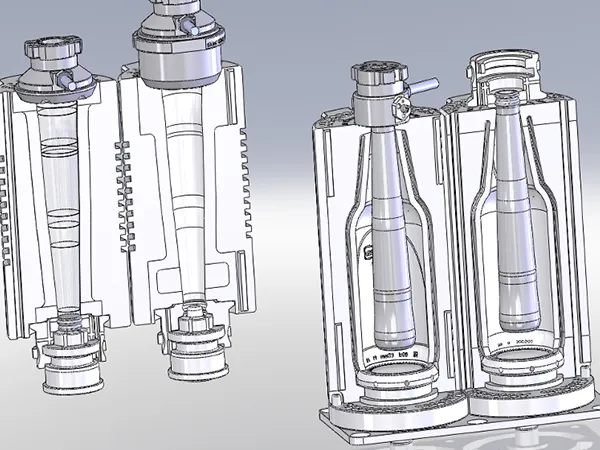

ORI Mould operates one of the world's most advanced intelligent casting facilities for producing high-quality materials. Our fully automated foundry integrates industry-standard equipment from Japan, Germany, Denmark, and Italy, including electric furnaces, automated mould forming line, intelligent casting systems, automated sand treatment system and 5G Automated Guided Vehicles (AGVs) for transport. This digitalised process from raw material blending to automated transport of castings ensures exceptional precision and quality control at every stage.

Key Data and Capabilities

- Investment: €12.33 million

- Annual production capacity: 10,000 tonnes of alloy materials (8,000 tonnes of cast iron and 2,000 tonnes of cast bronze)

- Sand processing capacity: 35 tonnes per hour

- Melting capacity: 3 tonnes of molten iron per hour and 1.5 tonnes of molten copper per hour

- Mould production efficiency: 1 mould every 30 seconds

- Environmental standards: Fully compliant with the strictest ecological and environmental regulations