FMS System: Boosting Efficiency in Glass Moulds Manufacturing

By integrating advanced CNC automated flexible production line sourced from Europe, we have successfully enhanced production efficiency and ensured rapid delivery of high-quality moulds.

- Identifying the Challenge

In 2016, a longstanding European client expressed the need for faster delivery times and improved product quality of glass moulds to meet their growing market demands. - Implementing the Solution

To address these requirements, ORI Mould initiated a series of upgrades in 2017, introducing customised horizontal machining centres and integrating them with advanced flexible production lines sourced from Europe. These new systems incorporated automatic detection devices and tool identification systems, significantly improving the precision of mould positioning. To further optimise production efficiency, ORI Mould installed a 78-pallet system, enabling fully automated 24-hour production switching, along with an advanced scheduling system that dynamically prioritised production tasks. These innovations allowed continuous, uninterrupted 24/7 glass module manufacturing operations. - Delivering Results

The enhancements achieved remarkable outcomes, delivery times were reduced, enabling 15 days expedited production for urgent orders, while monthly production capacity of the intelligent manufacturing line alone increased to 5,000 blank & blow mould. Moreover, the upgrades led to significant improvements in glass mould quality, earning high praise from the client. This successful collaboration has strengthened the long-term partnership, which continues to thrive to this day.

This case highlights our commitment to meeting client needs through innovation, efficiency, and reliability.

Advancing Welding Technology at ORI Mould

Over the years, ORI Mould has refined its welding technology, transitioning from traditional methods to innovative solutions to address production challenges and meet evolving industry demands.

- First Phase: Traditional Manual Flame Welding

Before 2008, ORI Mould relied on traditional manual flame welding. While this method provided uniform weld layers and was well-suited for conventional applications, it revealed significant limitations as production scales grew. Manual operation made it difficult to maintain consistency in large-scale manufacturing, leading to risks such as weld seam detachment and quality inconsistencies that posed challenges to efficient production. - Second Phase: Plasma Transferred Arc (PTA) Welding

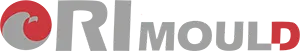

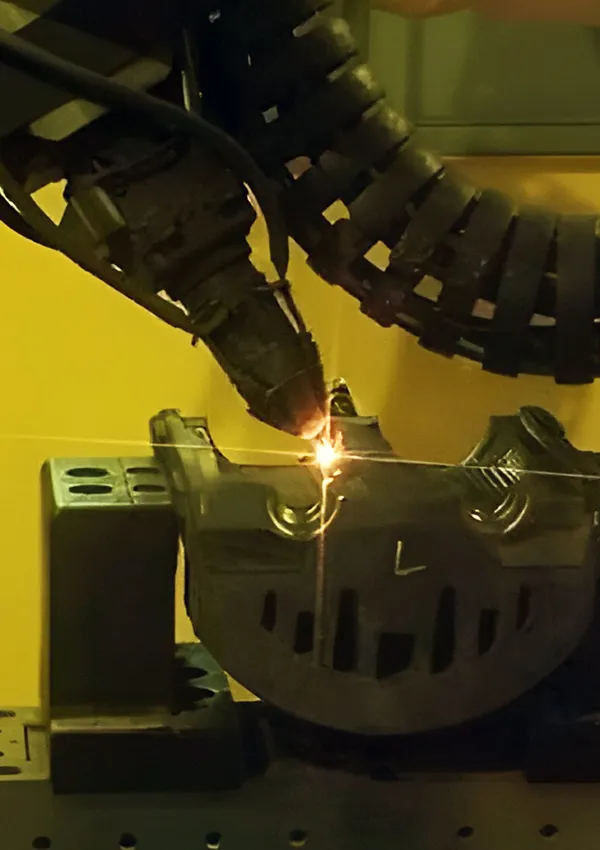

To overcome the limitations of manual welding, ORI Mould adopted plasma transferred arc (PTA) welding technology in 2009. This upgrade significantly enhanced the strength of welded joints. However, PTA welding introduced challenges of its own, including higher thermal impact on base materials and difficulties in controlling dilution rates. These factors occasionally led to uneven weld layers and quality fluctuations. - Third Phase: Laser Cladding

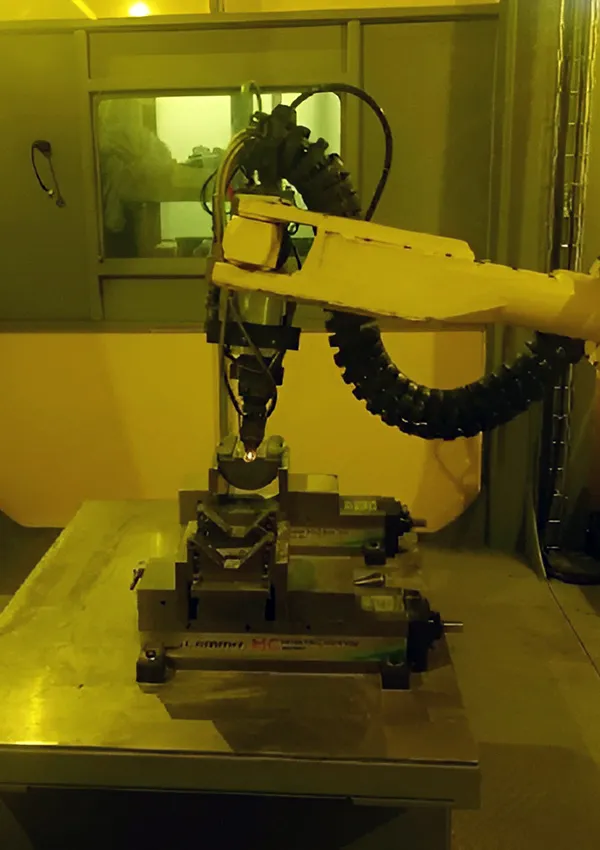

Following eight years of joint research with partners, ORI Mould transitioned to laser cladding technology in 2019. This advanced method combines the precision of manual welding with the efficiency of PTA welding. Laser cladding allows for precise control of weld layer dimensions and offers faster welding speeds, making it particularly suitable for narrow neck press and blow (NNPB) applications and high-speed production lines. It also significantly improves the aesthetic quality of bottle surfaces, especially at the seams. As a cold-welding technology, laser cladding minimises thermal damage, enabling us to meet the industry's increasingly stringent delivery schedules and quality standards. Through these advancements, ORI Mould has demonstrated a commitment to innovation and excellence, ensuring its welding techniques remain at the forefront of the glass mould manufacturing industry.