- The surface treatment process gives glass tableware a refined texture, enhancing both its appearance and quality.

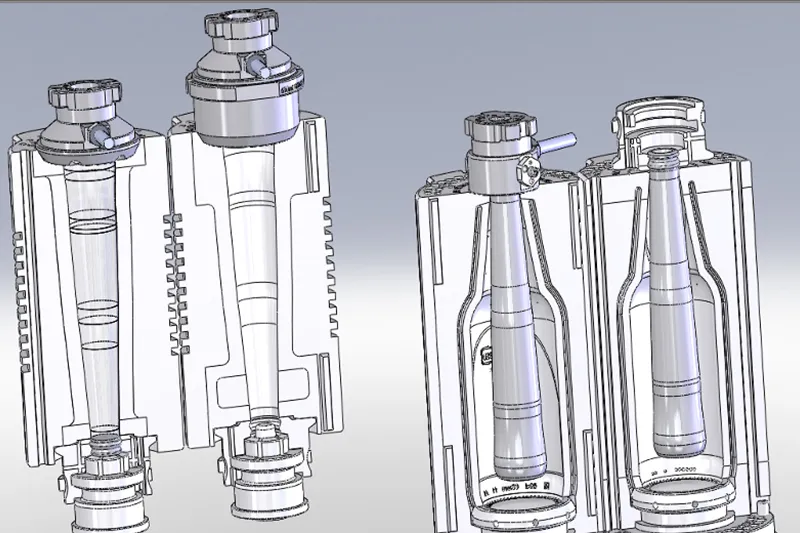

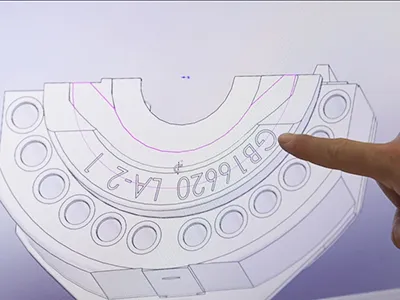

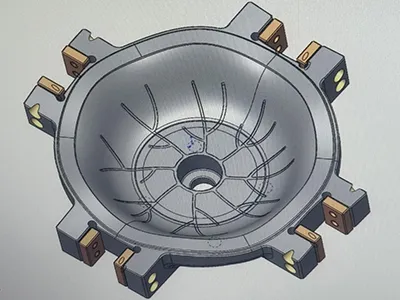

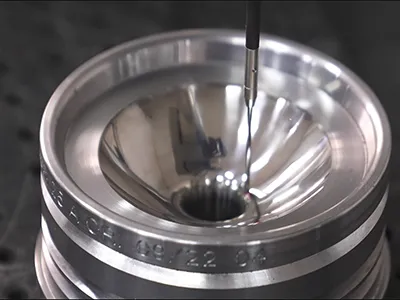

- Advanced machining techniques deliver precise cavities and complex shapes, ensuring the final product meets diverse aesthetic and functional needs.

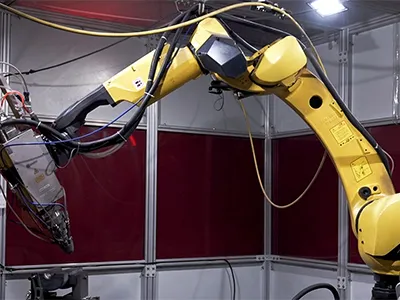

- By using stable and reliable casting methods, the moulds offer long-term durability and consistent results, even during continuous production.

To further enhance mould performance, we developed COC431 stainless steel, offering:

- A uniform microstructure that ensures consistent and dependable material performance, ideal for high-precision glass products.

- Low carbide content, improving toughness and corrosion resistance while extending the mould’s service life.

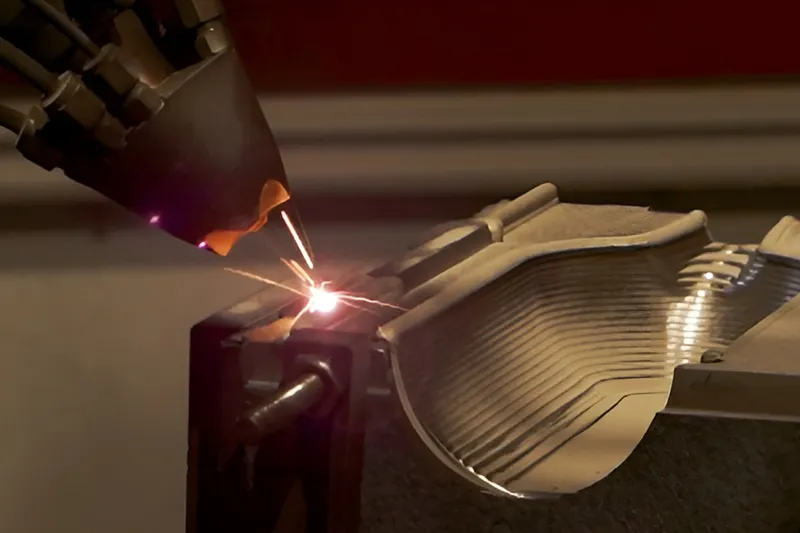

- Reduced ferrite content, which enhances flexibility in machining and welding, allowing for greater adaptability during production.

- High stability that prevents cracking, ensuring long-term reliability under extreme conditions and reducing maintenance costs.

- Cost-effectiveness, delivering strong value and meeting diverse production needs with improved return on investment.

Design

Design

Foundry and Casting

Foundry and Casting

Production

Production

Quality Control

Quality Control